AFS eliminate emissions from SBT assemblies in LNG train SBT inspection campaign Q1 2020

- A team of specialist small bore tubing inspectors were mobilised to the LNG plant prior to a planned maintenance shutdown.

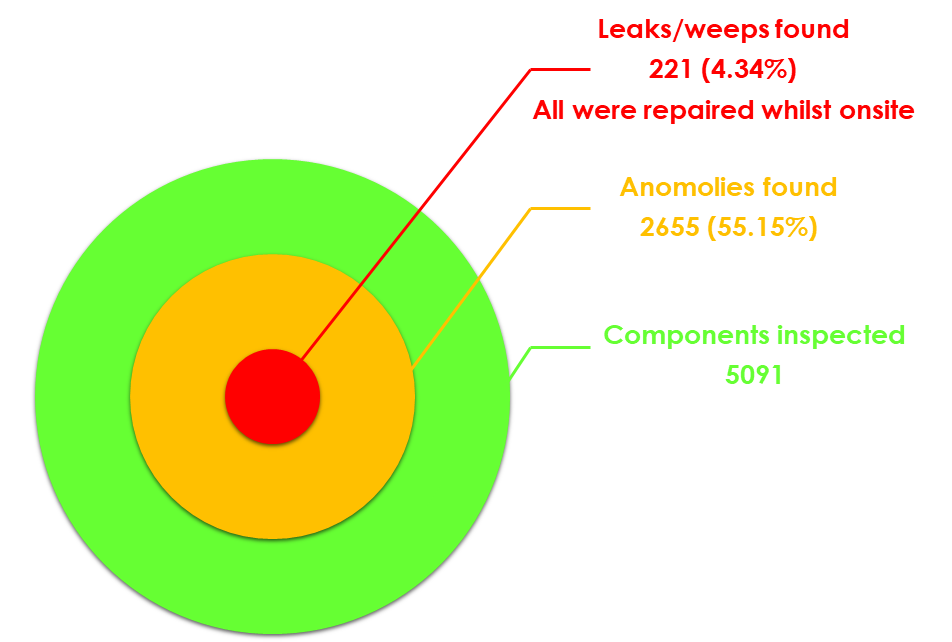

- Conducted a full visual inspection and leak detection survey of all accessible hydrocarbon-containing assemblies. Over 5000 components were inspected.

- All anomalies were tagged with a barcoded label and photographed

- All results were recorded on our bespoke EX-rated handheld pads and uploaded to our cloud-based SBT management database.

- A risk-based remedial action plan was generated by the management database and agreed with the client using the data gathered during the inspection process, including material and labour requirements

- During the train shutdown all high priority anomalies were repaired

- A record of the completion of each repair, including the remedial actions was recorded, signed off digitally and uploaded to the Cloud-based SBT management database

Outcomes and initiatives included:

- Implement a competence-based training and testing regime using the ECITB Route to Competence for Small Bore Tubing delivered by AFS Training Group

- Ensure all site contractors have successfully completed ECITB technical competence tests prior to site entry

- Low priority repairs to be completed whilst operational and verified by AFS on next visit

- Develop a technical standard for the management of SBT assemblies

- An ongoing program of risk-based inspections will be planned through the AFS cloud-based data management system