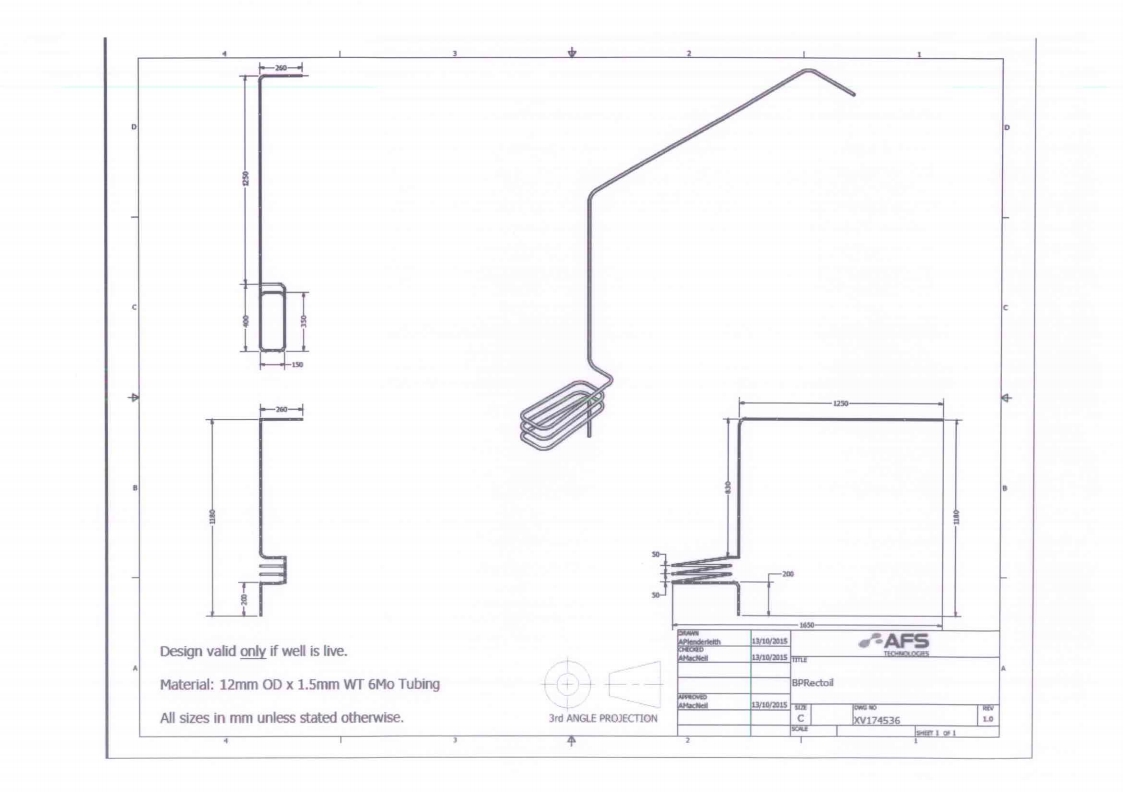

Challenge: A UK Oil company had a major hydrocarbon release due to the failure of a helical coil on a wellhead impulse line due to large scale deflection caused by thermal expansion of the production riser.

Approach: The operator contracted AFS Technologies and a vibration consultant to develop a solution. Our team built a test rig in our Aberdeen facility and provided SBT expertise to test the performance of tubing of differing materials, sizes and configurations, followed by FEA and stress analysis.

Result: The data collected allowed AFS Technicians to re-engineer the tube installation on all of the wellheads on the platform where the original failure occurred. The data also led to a published recommendations in the Energy Institute Guidelines for the design, installation and management of small bore tubing assemblies